Do you know about aluminum laminated film?

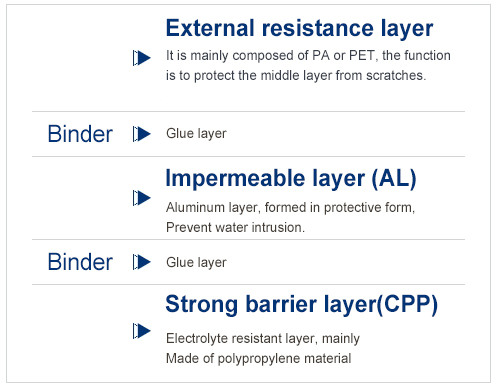

Aluminum plastic composite film, abbreviated as aluminum laminated film, is a composite soft packaging shell material used for lithium-ion batteries, commonly used in soft pack batteries and blade batteries. Sealing the assembled single cell with aluminum-plastic film can play an important role in protecting the internal electrodes and isolating the external environment. Due to the fact that the material used to package the battery cell needs to resist the swelling, dissolution, and absorption of the electrolyte, while ensuring strict barriers between oxygen and moisture, the aluminum-plastic film must have five major characteristics: puncture resistance, high barrier resistance, electrolyte resistance, high temperature insulation resistance, and high cold stamping.

CPP film has the following characteristics: uniform thickness and good flatness, low crystal point impurities; Soft and impact resistant, resistant to stress and whitening; High heat sealing strength.

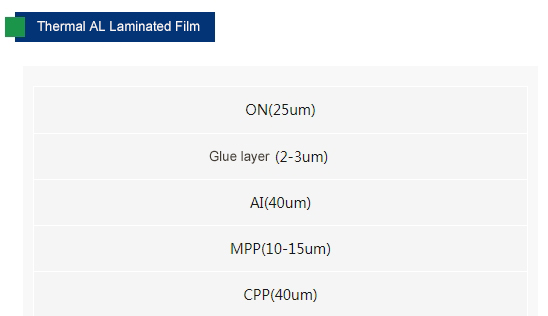

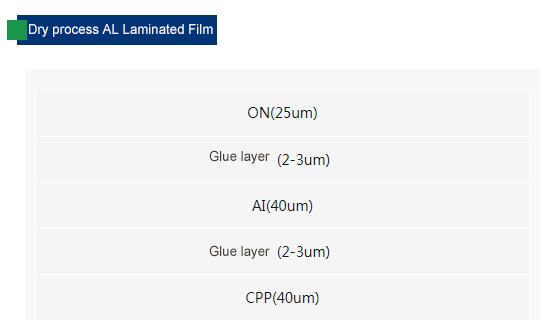

Aluminum plastic film can be divided into two types based on different manufacturing processes: dry process and hot process. The dry process involves directly adding a binder between the PP and aluminum layers for direct composite, using insulation binder, without the need for high temperature treatment. The anti short circuit performance is better than that of the hot process. And the ductility of the adhesive itself is better than that of the PP layer, which does not require high-temperature treatment and does not affect the molding. The thermal process involves bonding the aluminum layer and CPP layer with MPP and synthesizing them by hot pressing at a certain temperature. Under high temperature, the van der Waals force in MPP is destroyed, aged, and the short-circuit resistance performance will sharply decrease. Meanwhile, due to the destruction of its molecular structure, its toughness is reduced and it is prone to fracture during the molding process.

Aluminum plastic film structures with different processes:

The application characteristics of aluminum laminated film:

(1) Better safety performance. Due to the presence of multiple layers of plastic film, aluminum-plastic composite film soft packaging has good ductility. There will be no major safety issues such as explosions or fires, but rather air bubbles in the packaging or tearing at the sealing area and releasing energy.

(2) Small thickness, high volume to energy ratio. The thickness of traditional battery shells is relatively large, making it difficult to make technological breakthroughs in reducing thickness. The thinnest layer is around 3.6mm, while the thickness of aluminum-plastic composite film can reach below 1mm, resulting in larger battery capacity for the same volume.

(3) Lightweight, with a higher mass to energy ratio. Aluminum plastic composite film uses a large number of non-metallic materials, with a density much lower than that of metals. Low density, light weight, and high energy make it more suitable for portable devices.

(4) High space utilization rate. Aluminum plastic composite film flexible packaging can develop new battery cell models with greater freedom according to the design packaging size, and can even be customized according to the shape of the battery equipment used, and can produce special-shaped batteries.

(5) High discharge current and high platform. The interior of the flexible packaging battery is in a vacuum state, with a tighter connection between the positive electrode, separator, and negative electrode, lower internal resistance, and more effective release of discharge current and platform. According to data, the discharge capacity of flexible packaging lithium-ion batteries is about 10% higher than that of traditional hard shell lithium-ion batteries under the same volume.

(6) Long storage period. The flexible packaging battery is in a completely sealed state, with low internal resistance, which reduces the battery's self consumption.

Application example of aluminum laminated film: