BT-153-P 153μm

Product Characteristics

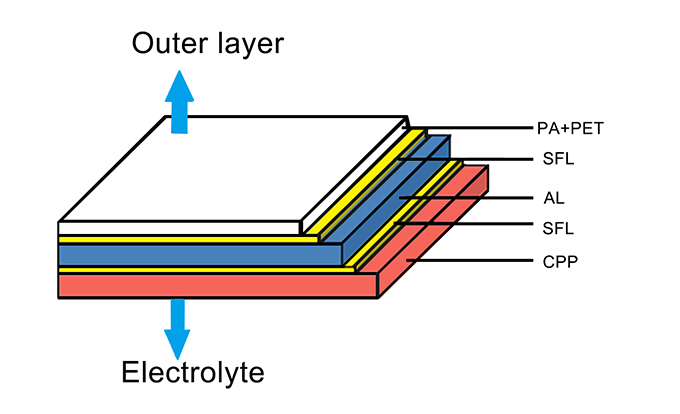

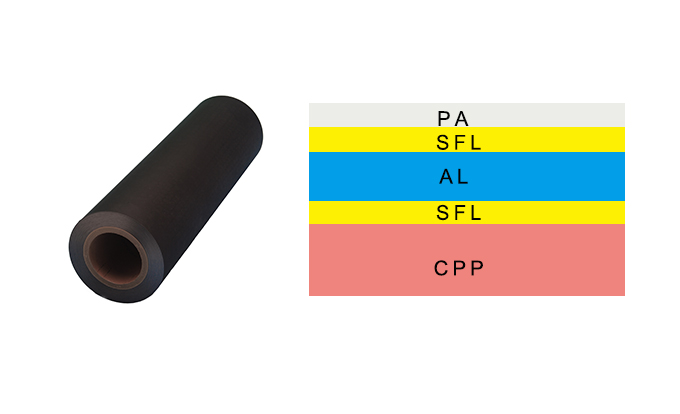

high barrier, good formability, electrolyte resistance

Product Category

Black film 153 μm

Product details

153μm

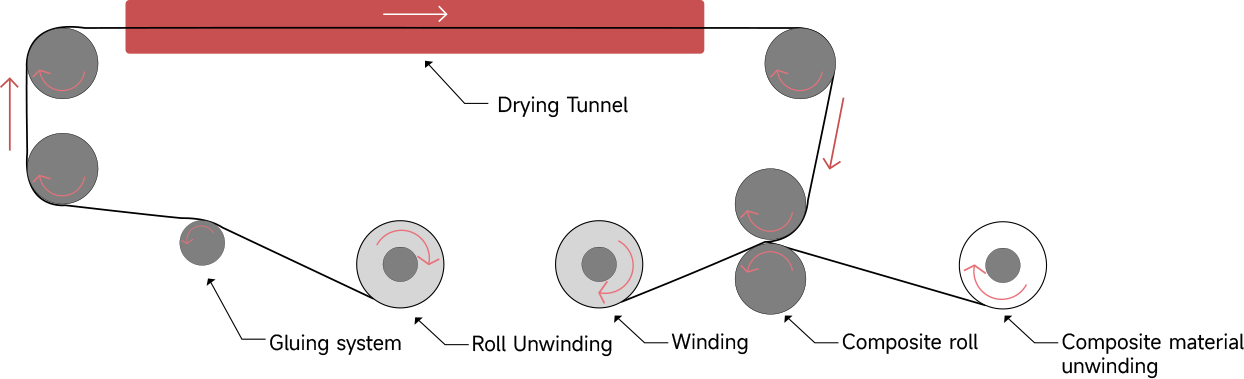

Dry Process 153μm aluminum pouch film for power battery packaging.

| Item | Unit | Typical Values | Performance | |||

| Btree | D*P | SH*WA | ||||

| Size | Thickness | % | ±5 | ±10 | ±10 | Product reliability and stability |

| Width | mm | ±1 | ±1 | ±1 | ||

Bubbles/ Objects | mm | Objects≤1.0 Bubble≤1.0 | diameter ≤0.5PP bubble≤1.0 | Colored objects≤1.0 Colorless objects≤2.0 Fibre objects≤2.0 | ||

Punching depth | Punching depth | mm | ≥6 | ≥6 | ≥4.4 | Stamping performance |

Residual thickness | % | ≥50 | / | / | Barrier capability | |

AL/CPP Peel strength | OriginalPeel Strength | N/15 mm | ≥15 | ≥5 | ≥5 | Product reliability and stability |

Electrolye Peel Strength | N/15 mm | ≥8 | ≥4 | Not layered | ||

PA/AL Peel strength | OriginalPeel Strength | N/15 mm | ≥3 | ≥3 | ≥2 | |

| Boiled | —— | 65℃ 7 days | / | / | ||

High temperatue and humidity | —— | 85℃ 85RH 7days | / | / | ||

Sealing Strength | Original sealing | N/15 mm | ≥70 | ≥50 | ≥29.4 | |

Electrolyte sealing | N/15 mm | ≥50 | ≥40 | / | ||

coefficient of friction | PA | —— | ≤0.3 | ≤0.3 | / | |

| CPP | —— | ≤0.3 | ≤0.3 | / | ||